Regular equipment assessments are essential for maintaining the performance reliability of any machinery. These detailed evaluations allow for the early detection of potential issues before they escalate. By resolving malfunctions promptly, organizations can prevent costly repairs, ultimately boosting reliability.

- Scheduled inspections should entail a variety of procedures

- Skilled engineers are necessary for conducting thorough assessments

- Record-keeping is critical for tracking progress

Thorough Mechanical Inspection Services for Critical Assets

Ensuring the reliability read more and longevity of critical assets is paramount in numerous industries. To achieve this, businesses require comprehensive mechanical inspection services. These services embrace a wide variety of techniques designed to detect potential issues before they deteriorate. A skilled inspection team utilizes advanced technologies to assess the condition of mechanical structures, providing valuable information to scheduled maintenance strategies. By committing in comprehensive mechanical inspection services, organizations can mitigate downtime, optimize safety, and maximize the lifespan of their critical assets.

Your Trusted Mechanical Inspection House

When it comes to ensuring the health of your mechanical systems, you need a team you can rely. That's where [Company Name] comes in. We are your dedicated mechanical inspection house, providing expert assessment and detailed solutions to keep your equipment running smoothly. Our experienced technicians employ the latest technology and industry best practices to detect potential problems before they become major issues.

- We offer a wide range of inspection services, tailored to meet the specific needs of your operations.

- From routine checkups to in-depth problem solving, we've got you covered.

- We are committed to provide you with clear, concise findings that outline our findings and recommend actionable steps.

Don't wait until a mechanical failure happens. Contact [Company Name] today for a free consultation and let us assist you in maintaining the productivity of your equipment.

Advanced Mechanical Thermography for Predictive Maintenance

Predictive maintenance strategies are increasingly vital in minimizing downtime and maximizing the operational efficiency of complex mechanical systems. Advanced mechanical thermography has emerged as a effective tool within this framework, leveraging the ability to detect minute temperature variations across equipment surfaces. By analyzing these thermal patterns through specialized imaging techniques, technicians can identify early issues such as lubrication problems, friction hotspots, and impending component failures. This proactive approach allows for timely intervention, preventing costly repairs and ensuring the continued reliable performance of critical machinery.

Unveiling Hidden Defects with Precision Mechanical Inspections

Within the realm of mechanical engineering, identifying hidden defects is paramount to ensuring the integrity and reliability of structures and systems. Precision mechanical inspections serve as an indispensable tool for uncovering these elusive flaws that may not be readily apparent through visual examination alone. Employing a suite of sophisticated techniques, inspectors meticulously analyze components at a microscopic level, seeking minute imperfections that could compromise performance or lead to catastrophic failures. From ultrasonic testing and eddy current inspection to magnetic particle analysis and radiographic examination, each method delivers unique capabilities in highlighting the presence of cracks, voids, inclusions, and other defects. By utilizing this arsenal of precision tools, engineers can ensure the structural soundness of mechanical systems, preventing potential hazards and prolonging their operational lifespan.

Detecting Thermal Anomalies: The Power of Mechanical Thermography

Mechanical thermography leverages the science of heat transfer to reveal hidden defects and anomalies within mechanical systems. This non-destructive testing approach measures the temperature variations on a surface, highlighting areas that are undergoing different thermal characteristics compared to their surroundings.

By analyzing these patterns, technicians can detect potential problems such as friction issues, electrical problems, or structural weaknesses. Mechanical thermography offers a versatile and effective method for predictive maintenance, helping to minimize downtime and improve overall system performance.

Rick Moranis Then & Now!

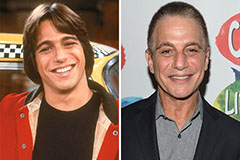

Rick Moranis Then & Now! Tony Danza Then & Now!

Tony Danza Then & Now! Mike Vitar Then & Now!

Mike Vitar Then & Now! Nancy Kerrigan Then & Now!

Nancy Kerrigan Then & Now! Nadia Bjorlin Then & Now!

Nadia Bjorlin Then & Now!